|

|

|

| |

Power tong Power tong |

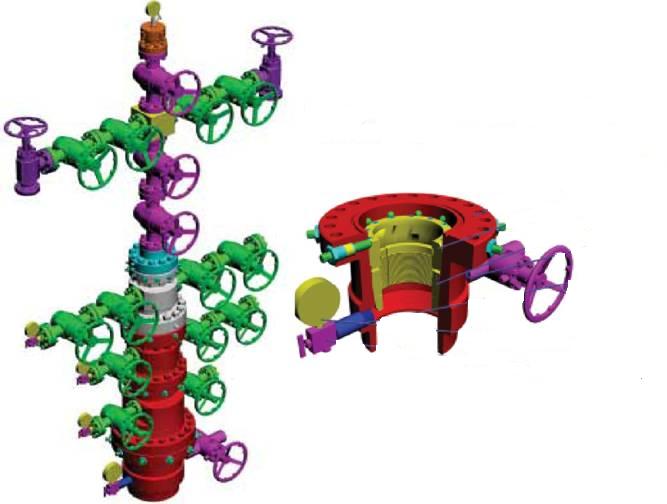

Hydraulic Drill Pipe Tong

Based on Varco Big Foot,The Iron Roughneck working principal, our Power Drilling Tong is a safer, more efficient system for tripping pipe. A combination of the proven Hydraulic spinning wrench and the hydraulic torque wrench, it provides fast, accurate stabbing and quick, controlled spin up. Pipe can be torqued to precise, consistent values without creating bending stresses in the drilling string. That alone can save you a lot of tool joints and drill pipe. Comparing to Varco Big Foot,The Iron Roughneck, our power tong is more compact, more easier to instal and operate and more less maintenance job required but with all perfect features of Big Foot being applied.

By using such Power tong, Rig floow hazards casued by the spinning chain, the tongs and tongs lines are eliminated.

The power tong is hydraulically powered, so speed control is smooth and variable. You can adjust for fast spin up of drill pipe or slow, controlled spin up for "walking-in" drill collars. This minimizes cross-threading, "thread burn" and permit proper spin up of the engaged threads- all crtitical factors in the longevity of expensive tool joints.A fully reversible feature permits pipe to be spun out intead of rotating out with the table, avoiding possible damage to the wall cake and eliminating hazardous floor conditions.

To adjust the height of tong, one Hydraulic Hanger is designed

|

|

|

Power tong |

ZQ203-125-I

|

ZQ203-100-I

|

ZQ203-100-II

|

|

Size Rang |

in |

5~8

|

5~8

|

5~8

|

|

mm |

127-203

|

127-203

|

127-203

|

|

Max. Torque |

lb-ft |

92,200

|

73,750

|

73,750

|

|

kN.M |

125

|

100

|

100

|

|

Rotating Speed (RPM) |

Hi-Gear |

40

|

40

|

40

|

|

Lo-Gear |

2.7

|

2.7

|

2.7

|

|

Hydraulic system working pressure rated |

psi |

2,900

|

2,400

|

2,400

|

|

Mpa |

20

|

16.6

|

16.6

|

|

Hydraulic system flow rate |

LPM |

114

|

114

|

114

|

|

GPM |

30

|

30

|

30

|

|

Stroke of shifting cylinder |

mm |

1,500

|

1,500

|

1,500

|

|

in |

59

|

59

|

59

|

|

Moving distance of tong |

mm |

-

|

-

|

-

|

|

in |

-

|

|

|

|

Up-down distance of tong |

mm |

|

|

0-485

|

|

in |

|

|

0-19

|

|

Weight |

kg |

2,600

|

2,400

|

2,500

|

|

lb |

5,730

|

5,290

|

5,510

|

|

Overall Dimensions |

mm |

1720*1050*1750

|

1700*1000*1400

|

1700*1000*1400

|

|

in |

68*41*69

|

67*39*55

|

67*39*55

|

|

Power tong |

ZQ230-100-III

|

ZQ162-50

|

ZQ127-25

|

|

Size Rang |

in |

5~8

|

2 3/8~5

|

2 3/8-5

|

|

mm |

127-203

|

85-162

|

65-127

|

|

Max. Torque |

lb-ft |

73,750

|

36,880

|

18,440

|

|

kN.M |

100

|

50

|

25

|

|

Rotating Speed (RPM) |

Hi-Gear |

40

|

60

|

65

|

|

Lo-Gear |

2.7

|

4.1

|

10.5

|

|

Hydraulic system working pressure rated |

psi |

2,400

|

2,320

|

1,740

|

|

Mpa |

16.6

|

16

|

12

|

|

Hydraulic system flow rate |

LPM |

114

|

120

|

180

|

|

GPM |

30

|

32

|

48

|

|

Stroke of shifting cylinder |

mm |

-

|

1,000

|

1,000

|

|

in |

-

|

39.4

|

39.4

|

|

Moving distance of tong |

mm |

0-1,500

|

|

|

|

in |

0-59

|

|

|

|

Up-down distance of tong |

mm |

0-800

|

|

|

|

in |

0-31.5

|

|

|

|

Weight |

kg |

3,250

|

1,500

|

620

|

|

lb |

7,165

|

3,310

|

1,360

|

|

Overall Dimensions |

mm |

1750*1650*2050

|

1570*800*1190

|

1110*790*820

|

|

in |

69*65*81

|

62*31*47

|

44*31*42

|

|

Hydraulic Casing Tong

Our power casing tong is machined by feautures-combining of Eckel, weatherfold, and Farr designs as below Spec.

|

|

Casing Tong |

TQ178-16

|

TQ340-20Y

|

TQ340-35

|

|

Size Rang |

in |

4~7

|

4~13 3/8

|

5 1/2~13 3/8

|

|

mm |

101.6~178

|

101.6~340

|

139.7~340

|

|

Hydraulic system working pressure |

Mpa |

18

|

16

|

18

|

|

psi |

2,610

|

2,320

|

2,610

|

|

Hydraulic system flow rate |

LPM |

114

|

114

|

114

|

|

GPM |

30.1

|

30.1

|

30.1

|

|

Max. Torque |

Hi-Gear |

lb.ft |

1,770~2,200

|

2,730

|

1,844~2,200

|

|

KN.m |

2.4~3

|

3.7

|

2.5~3

|

|

Mi-Gear |

lb.ft |

-

|

-

|

4,420~5,530

|

|

KN.M |

-

|

-

|

6.0~7.5

|

|

Lo-Gear |

lb.ft |

11,800

|

14,750

|

25,800

|

|

KN.M |

16

|

20

|

35

|

|

Rotating Speed |

Hi-Gear |

RPM |

54~79

|

50~80

|

60~86

|

|

Mi-Gear |

RPM |

|

|

21~30

|

|

Lo-Gear |

RPM |

9~13.1

|

6~14

|

2.6~5.3

|

|

Overall Dimensions |

mm |

1540*760*740

|

1520*850*670

|

1540*900*860

|

|

in |

61*30*29

|

60*34*26

|

61*36*34

|

|

Weight |

lb |

1280

|

1234

|

1720

|

|

Kg |

580

|

560

|

780

|

|

Casing Tong |

TQ178-16Y

|

TQ340-35Y

|

|

Size Rang |

in |

4~7

|

4~13 3/8

|

|

mm |

101.6~178

|

101.6~340

|

|

Hydraulic system working pressure |

Mpa |

18

|

18

|

|

psi |

2,610

|

2,610

|

|

Hydraulic system flow rate |

LPM |

114

|

114

|

|

GPM |

30.1

|

30.1

|

|

Max. Torque |

Hi-Gear |

lb.ft |

1,770~2,200

|

2,950~3,680

|

|

KN.m |

2.4~3

|

4.0~5.0

|

|

Mi-Gear |

lb.ft |

-

|

-

|

|

KN.M |

-

|

-

|

|

Lo-Gear |

lb.ft |

11,060~13,280

|

19,900~22,120

|

|

KN.M |

15~18

|

27~30

|

|

Rotating Speed |

Hi-Gear |

RPM |

54~79

|

80~98

|

|

Mi-Gear |

RPM |

|

|

|

Lo-Gear |

RPM |

8.5~12

|

12~16

|

|

Overall Dimensions |

mm |

1500*750*680

|

1560*900*850

|

|

in |

59*30*27

|

61*35*33.5

|

|

Weight |

lb |

1250

|

1720

|

|

Kg |

570

|

780

|

|

Hydraulic Tubing Tong

By introducing Eckel design, we developed our own Hydraulic Tubing tong with the following spec.

|

|

Tongs |

XYQ1.8

|

XYQ3C

|

XYQ6B

|

XYQ12A

|

|

Pipe Range for Master tong |

1 7/8~2 3/8

|

2 3/8~3 1/2

|

2 7/8~4 1/2

|

2 7/8~5 9/16

|

|

Pipe range for Back-Up Tong |

-

|

2 7/8~4 1/2

|

3 1/2~5 9/16

|

3 1/2~6 1/8

|

|

Hi-Gear rated Torque (lb-ft) |

519

|

812

|

1,107

|

1,919

|

|

Lo-Gear rated Torque (lb-ft) |

1,336

|

-

|

-

|

8,856

|

|

Hi-Gear Max. Rotating Speed (RPM) |

100

|

100

|

85

|

68

|

|

Lo-Gear Max. Rotating Speed (RPM) |

40

|

30

|

20

|

13

|

|

Opening size of Master tong |

2 3/8

|

3 3/4

|

4 5/8

|

5 7/8

|

|

Opening Size of Back-up tong |

-

|

4 9/16

|

5 11/16

|

6 1/4

|

|

Rated working pressure (psi) |

1,430

|

1,430

|

1,573

|

1,573

|

|

Max. Oil Supply (GPM) |

17.60

|

17.60

|

22.00

|

26.40

|

|

Overall Dimensions (mm) |

543*334*404

|

733*420*550

|

850*480*600

|

1042*582*839

|

|

Gross Weight (kg) |

87

|

160

|

240

|

485

|

|

Power Station

Hydraulic Drill pipe tong, Hydraulic Casing tong and Hydraulic Tubing tong could get power from the same power station. There are 2 different designs which will be used for each different cases. Furthermore, the explosion-proof motor can be alternated by Diesel Engine as per the working conditions. Both 50 HZ and 60 HZ explosion-proof motor are available.

|

|

FYZ-120B Air Cooled Power Unit is used when the working enviroment temperature above 45 degrees. |

. .

|

YZB-120 Power Unit is used when the working enviroment temperature below 45 degree |

|

Power Station |

YZB-120

|

FYZB-120

|

|

Max. Working Pressure |

Mpa |

20

|

20

|

|

psi |

2,900

|

2,900

|

|

Flow rate |

LPM |

120

|

120

|

|

GPM |

31.7

|

31.7

|

|

Oil volume |

L |

587

|

587

|

|

Gallon |

155

|

155

|

|

Motor for Air-cooled system |

KW |

|

1.1

|

|

HP |

|

1.5

|

|

Explosion-proof motor |

KW |

37

|

37

|

|

HP |

50

|

50

|

|

Overall Dimensions |

mm |

1720*1050*1155

|

1530*745*955

|

|

in |

68*41*46

|

60*29*38

|

|

Weight |

Kg |

1,300

|

1,500

|

|

lb |

2,866

|

3,307

|

|

|

| |

|

|

|

|