|

|

|

| |

Stabilizer Stabilizer |

|

Stabilizer

Stabilizers are made from premium chrome molybdenese alloy steel (except for non-magnetic style), heat treated by special procedures and obtain expected hardness, strength and impact value properties. All threads are made strictly in accordance with API Spec. the hardbanding of stabilizer employ "pressed in" Tungsten Carbide alloy buttons or other anti-wear materials. All stabilizers should be ultrasonic tested.

-

Integral spiral stabilizer

-

Integral Mandrel Sleeve Stabilizers

-

Two pieces Mandrel sleeve stabilizers

-

Interchangeable sleeve stabilizers

-

Sleeve stabilizer

-

Integral straight Rib Stabilizer

Integral Spiral Stabilizer

Integral Spiral Stabilizer is made from AISI 4145 H Modified alloy steel or non-magnetic alloy steel, the pressure button type or applied Tungsten Carbide hardbanding on the blade facing are available. The non-magnetic stabilizers have special hardbanding on the spiraled blade surface that the magnetic properties have been eliminated.

Tow-pieces Construction Integral Stabilizer

The size 26" and bigger Integral Stabilizer constructed of tow pieces .The sleeve on witch made four spiral blades is attached to the body with a shrink fit. To install sleeve, it must be heated up to 400℃. So that the sleeve is never disassemble.

The body (or mandrel) is made of modified alloy steel, then fully heat-treated with the following properties:

|

|

Hole Size (in)

|

Std. DC Size (in)

|

Wall Contact (in)

|

Balde width (in)

|

Fishing Neck Length (in)

|

Blade undergage (in)

|

Overall Length (in)

|

Approx. WT. (kg)

|

|

String

|

Near-Bit

|

|

6~6 3/4

|

4 1/2~4 3/4

|

16

|

2 1/4

|

28

|

-1/32

|

74

|

70

|

165

|

|

7 1/2~8 1/2

|

6 1/2

|

16

|

2 1/2

|

28

|

-1/32

|

75

|

70

|

350

|

|

9 1/2~12 1/4

|

8

|

18

|

3 1/2

|

30

|

-1/32

|

83

|

78

|

750

|

|

14 3/4~17 1/2

|

9 1/2

|

18

|

4

|

30

|

-1/32

|

92

|

87

|

1000

|

|

20~26

|

9 1/2

|

18

|

4

|

30

|

-1/32

|

100

|

95

|

1800

|

|

Order Instructions:

-

Hole size and type (String or near-Bit)

-

Drill Collar OD and ID

-

Size and type of Connection

-

The API Stress relief groove or bore back

-

Bore for float valve

-

Hardbanding type.

|

|

Sleeve Type Stabilizers

Sleeve type Stabilizers are made of 4145H modified alloy steel. Heat treated to 285~341 BH and 54 Joules minimum impact value. The stabilizers consists of one piece body (Mandrel) and one sleeve which is jointed, the sleeve can be changed after fretted.

Order Instructions:

-

Hole size and type (String or Near Bit)

-

Drill Collar OD and ID

-

Size and type of connections

-

Hard facing type

-

Sleeve Breaker

|

|

Hole size (in)

|

DC OD (in)

|

Upset Dia. (in)

|

Bottom Neck Dia.(in)

|

Overall Length (in)

|

Fishing Neck Length (in)

|

Approx. WT. (kg)

|

Sleeve Length (in)

|

|

String type

|

Near-Bit

|

|

6 1/4~7 1/2

|

4 3/4~5

|

5 3/4

|

4 3/4

|

65

|

27

|

22

|

125

|

14

|

|

8 1/2~9 7/8

|

6 1/4~6 3/4

|

7 1/2

|

6 1/4

|

65

|

27

|

22

|

220

|

14

|

|

8 1/2~9 7/8

|

6 1/2~7 1/4

|

7 3/4

|

6 1/2

|

65

|

27

|

22

|

260

|

14

|

|

12 1/4~17 1/2

|

7 3/4~8 1/4

|

9 1/4

|

7 3/4

|

66

|

27

|

22

|

370

|

16

|

|

12 1/4~17 1/2

|

8 1/2~9

|

9 7/8

|

8 1/2

|

66

|

27

|

22

|

460

|

18

|

|

14 3/4~20

|

9 1/2~10

|

11

|

9 5/8

|

66

|

27

|

22

|

550

|

22

|

|

Interchangeable Sleeve Stabilizers

Interchangeable Sleeve Stabilizers are made of 4145H modified Alloy steel. Heat treated to 285~341 Brinell Hardness and 54 Joules minimum impact value. The physical properties would be guaranteed 1 inch below the surface. Such kinds of stabilizers consist of two pieces which are jointed by the center connection and one sleeve. Every stabilizers is equipped with a certain sizes of sleeve.

Order Instructions:

-

Hole Size and type (String and near-Bit)

-

Drill Collar OD and ID

-

Size and type of connection

-

Hard facing type

|

|

Hole Size (in)

|

Sleeve

|

Body (Mandrel)

|

Overall Length (in)

|

|

Balde width (in)

|

Length (in)

|

Approx. WT. (kg)

|

DC Size (in)

|

Bore (in)

|

Upset Dia. (in)

|

Center Conn.

|

Approx. WT. (kg)

|

|

6 1/8, 6 1/4~6 3/4

|

2

|

18

|

35

|

4 1/8, 4 3/4

|

2

|

4 3/4

|

2 7/8IF

|

125

|

64

|

|

7 3/8~7 3/4

|

2

|

18

|

45

|

5 3/4

|

2 1/4

|

5 3/4

|

3 1/2IF

|

180

|

66

|

|

8 1/2~8 3/4

|

2 3/8

|

18

|

55

|

6 1/2

|

2 13/16

|

6 3/4

|

4

|

250

|

68

|

|

9 1/2~11

|

2 3/4

|

18

|

65

|

7 1/4

|

2 13/16

|

7 1/2

|

4 1/2

|

330

|

68

|

|

12 1/4~15, 17 1/2

|

3 1/8

|

18

|

95

|

8, 8 1/2

|

2 13/16

|

8 1/2

|

6 5/8 Reg.

|

520

|

72

|

|

12 1/4~17 1/2

|

3 1/8

|

24

|

130

|

9 1/2

|

3

|

9 1/2

|

7 5/8 Reg.

|

550

|

81

|

|

17 1/2~20

|

4

|

33

|

180

|

11 1/4

|

3

|

11 1/4

|

8 5/8 Reg.

|

810

|

90

|

|

22~26

|

4

|

33

|

250

|

9 1/2

|

3

|

9 1/4

|

7 5/8 Reg.

|

615

|

90

|

|

Integral Straight Rib Stabilizers

Straight Rib Stabilizers are made of AISI 4145 H Alloy steel by one piece of integral bar. Every stabilizer has four straight ribs that pressed Tungsten Carbide buttons or other type of hardfacing is located on the surface of the ribs. Ultrasonic inspection is performed on each stabilizer.

|

|

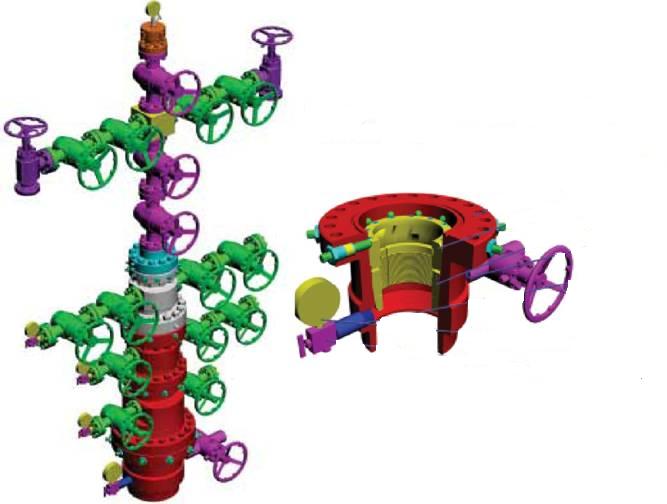

Variable Diameter Stabilizer Type KFQ

The stabilizer Diameter changes when WOB (Weight on Bit) works on stabilizer block, which will return back to its compact position when drilling string runs out of the hole

|

|

| |

|

|

|

|